The World's First 3D-Printed Eel Is On Its Way To Your Table

From Japanese unagi to jellied eels in East London, England, eating eels has long been a part of culinary history for people across the globe. But the industry currently faces a number of challenges, as well as growing demand. In 2022, the global eel market was worth $4.3 billion and is expected to reach $4.8 billion by the year 2028 (via Industry Research).

While there are differences between freshwater and seawater eel, and the majority of eel consumed across the world comes from farms, areas of concern include breeding struggles, as well as several species being flagged as endangered. But a new sustainable alternative is now on the horizon, as a pioneering Israel-based company has created the world's first 3D-printed eel using innovative bioprinting technology.

While the 3D-printed eel launched by Steakholder Foods in December 2023 is currently entirely plant-based, there are plans for it to include cultivated eel cells in the future. And, if able to be successfully mass-produced, it has the potential to revolutionize the seafood industry in a huge way.

Plant-based 3D-printed eel mimics the texture of real eel

Whether smoked or sauteed, one of the defining characteristics of eel, especially freshwater eel (known as unagi in Japan) is its soft, tender, almost velvety texture. And Steakholder Foods has used 3D-bioprinting technology to try to capture this unique texture in their plant-based 3D-printed eel, as well as replicating the taste and appearance of the real thing.

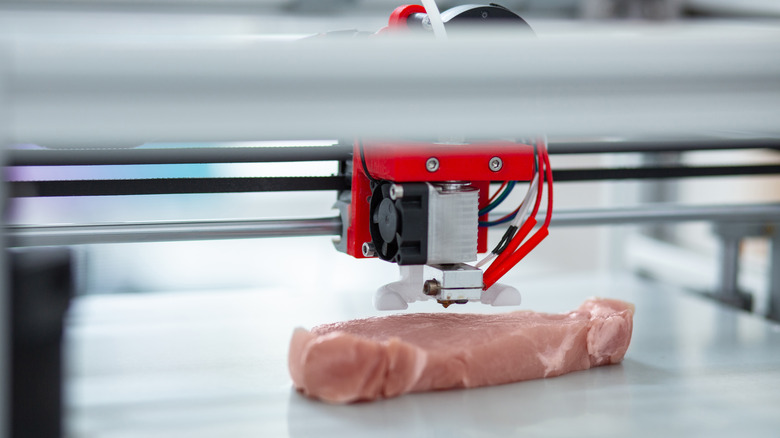

The method for 3D-printed meat and fish involves using plant-based and cultivated cells to form an innovative bio-ink, which a 3D printer then prints into a layered structure based on a digital design. The 3D-printed eel has been created using DropJet technology, specifically designed for seafood products, which uses gel-based drops to help create the finished structure that mimics the texture of fish.

Eel is not the only 3D-printed seafood to have been launched by Steakholder Foods, the first Nasdaq-listed cultivated meat company. In the summer of 2023, the company partnered with Singapore-based Umami Meats to create a ready-to-cook fish filet made using cultivated cells. And the previous year saw its launch of omakase beef morsels, inspired by the marbling of Wagyu beef, and printed using separate layers of muscle- and fat-based bio-inks.

Could 3D-printed eel be sustainably mass-produced?

While 3D-printed fish and seafood could become a more sustainable alternative for diners in the future, it could also help reduce costs for food companies in a competitive market. As the process expands and develops to include cultivated eel cells rather than being solely plant-based, it could become even more similar to the original product in terms of taste of texture.

Israel, where Steakholder Foods is headquartered, is already recognized as a leader when it comes to alternative meat production. And the company's CEO, Arik Kaufman, said in a statement that the innovation of 3D-printed eel is a "pivotal moment," with the potential to generate "hundreds of tons monthly" on a vast industrial scale (via press release).

Cultured meats using cells and biomaterials have already been touted as a way to produce real meat in a more sustainable way, made possible by rapid advances in food innovation and technology. And this latest seafood launch looks like it could be the real deal when it comes to eel.